Oil treatment of untreated wood

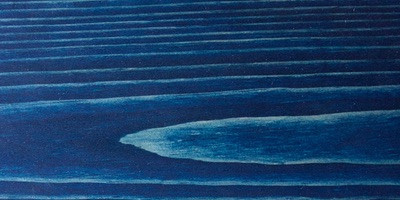

Colors and wood undeniably belong together, if you ask me. Colors can make even the most doll piece of pine come alive and give it new life, full of depth The colored oils give glow and renewed character to the wood. The veins in the wood come into play and give a fantastically beautiful expression, in combination with the colored oils. However, the colored oils can only be used on untreated wood, so varnish and any old soap treatment must be removed first before applying the colored oils.

|

|

|

I am almost equally surprised every time you wipe the excess oil off the surface, how wild it can affect the expression of the wood. However, wood is not just wood, the wood absorb the oil differently depending on the type of wood in question, and how it has been sanded. The smother the wood is sanded, the less it will absorb the colored oil. The type of wood also has a great impact on how the color will look. Oak, for example, takes on less color, while birch plywood takes on color strongly. It is always a good idea to make samples, to see how it looks on exactly the specific wood in question, if this is an possibility. The color strength of the colored oils does not only vary according to the type of wood and how the surface of the wood has been sanded before the application of the oil. It also depends on which pigments that are included in the oil. The erath pigments have less color power than some of the synthetically produced color pigments. At decor colors, we have a wide selection of colored transparent oils, ranging from classic tones to more daring and expressive colors. In connection with a small remodeling in the shop, I made some shelves and other interior items in bamboo which I chose to oil treat. You can see the result here. Among other things, I used our own oil called Sweet Honey. |

|

|

|

You can also "pre-water / moisten the wood" with a little water to make the pores in the wood open, then the wood will absorb more of the color. It is especially suitable for hardwood, which may well appear with a more "closed" surface due to the density of the wood. If you want to avoid too much yellowing of brighter woods types, you can advantageously treat the wood with lye first. It stops the Yellowing process in the wood, which will otherwise occur when it is exposed to sunlight for a long time. It will not stop the yellowing completely, but slow it down a lot. However, the method is mostly used when finishing with neutral oil (oil without color) or white and very light colored oils. |

|

Before applying the oil to the desired surface, it is important that the surface appears clean and dust-free. You should apply the oil in the longitudinal direction of the wood with a brush or a sponge, depending on what you find best. The oil must be applied in a thin layer, but no matter what, the surface will often appear stained after application (depending on how absorbent the substrate is). It is completely normal and it disappears at the next step in the process. After 20-30 minutes, wipe off all excess oil with a lint-free cloth. It will make the surface appear with an even and silky matte expression, and then just wait until the oil has been allowed to harden. It is always a good idea to let the oil harden for 2-3 days before using the furniture / table, etc. The oil is first fully cured after 3-4 weeks. And it is only then that the oil has attained its full strength. If you want a deeper and more opaque color, you can repeat the treatment after 24 hours. How much more color you can add to the surface depends on the ability of the wood to absorb. And it can be very different. Therefore, it is always a good idea to do a test before. NOTE! It is important to take care to destroy the cloths you have used for wiping immediately after they have been used, as cloths soaked in linseed oil can be self-igniting. Wet them with water and put them in a plastic bag with a knot on so that they do not can absorb oxygen. |

|

|

|

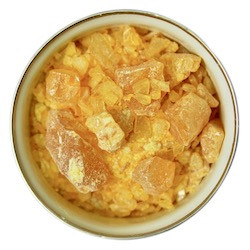

To get an even stronger and more durable surface, you can choose to give the surface a layer of linseed oil wax or a few coats of tonkin varnish. The wax will make the surface appear with a little more shine, while the tonkin varnish will have a direct glossy look. However, you can also mix the tonknin varnish with a matting additive (gelomat), so you get a less glossy look. Tonkin varnish is the most durable and water-repellent of the 2 finishing methods. Personally, I prefer Linseed wax, as it is easy and simple to work with, and gives a nice "feel" to the surface. Even though the tonkin varnish is more durable in the long run, but as I said, both are suitable. Enjoy BB |