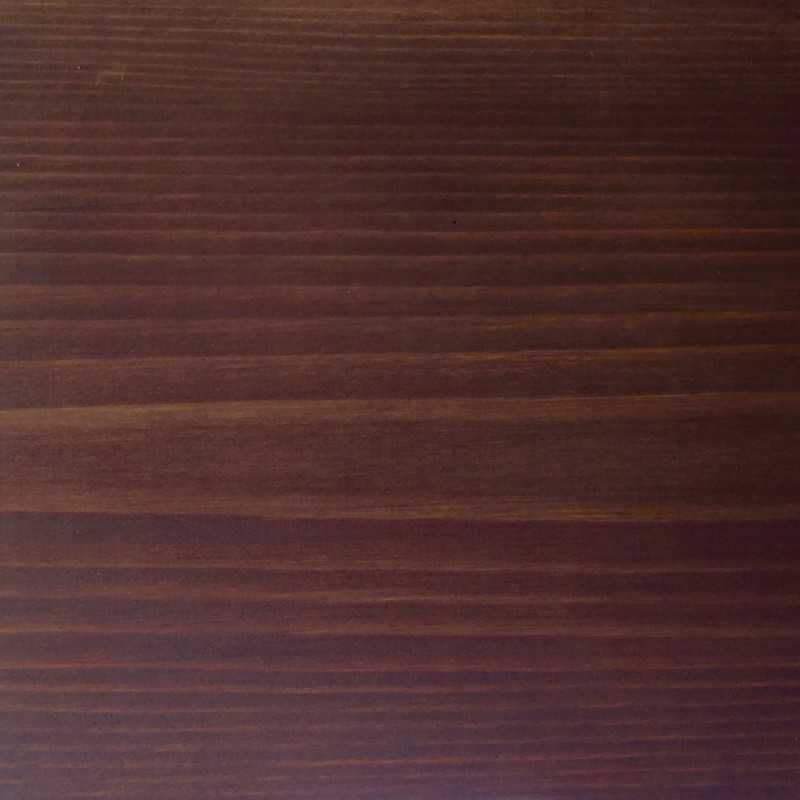

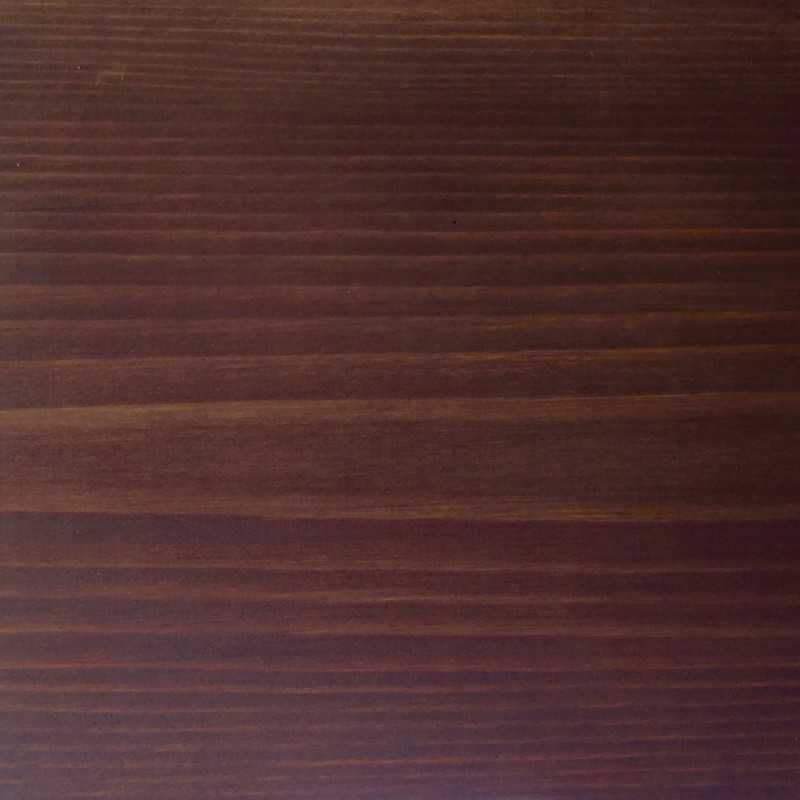

Pigmented oil for surface treatment of untreated wood.

We strive to deliver within 2-4 business days. NOTE! on wallpaper there is 7-14 days delivery time.

We have a 30 day return policy. Tinted paint and wallpaper are an exception. They cannot be returned

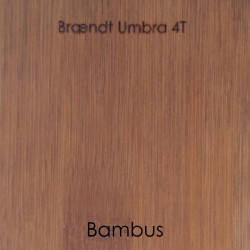

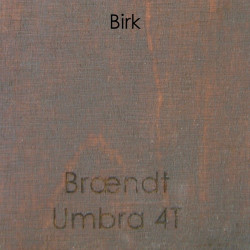

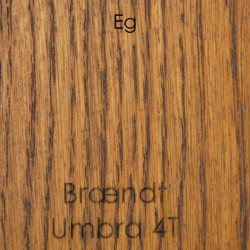

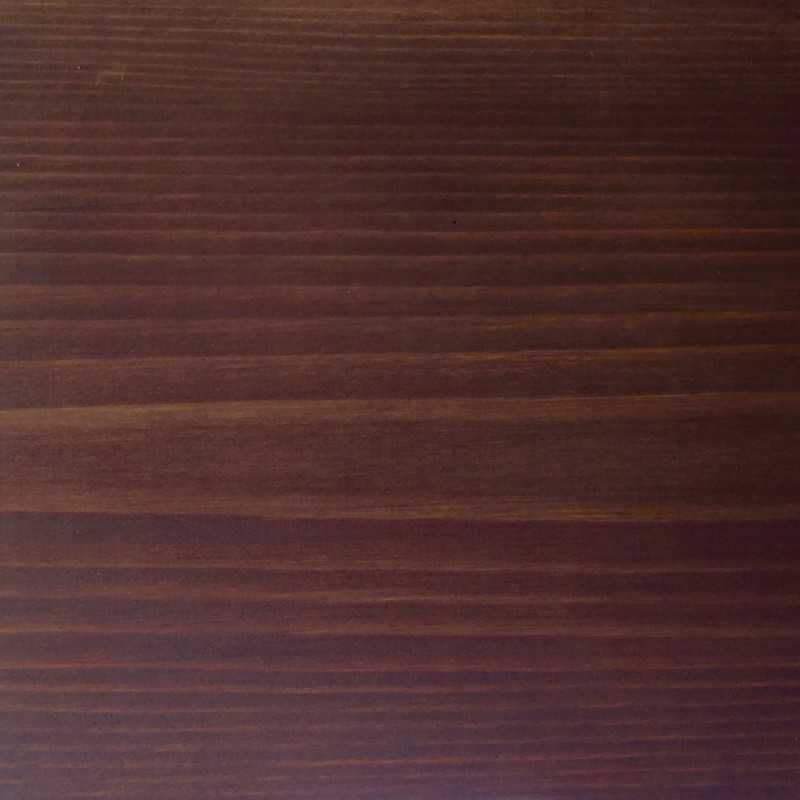

Attention; There can be a big difference between how a color is represented on a screen and how it is experienced in real life. It is important to keep in mind when choosing color.

Transparent oil from decor colors is a diffusion-open and pigmented oil, based on linseed oil and color pigments. Transparent oil is used on raw, untreated woodwork indoors & outdoors, where you want the wood's natural veining and structure to play with and remain visible through the colored oil. Transparent oil is available in many colors. See the selection in the store and here on the web shop. For outdoor use, fungicides can be added as desired.

Transparent oil contains neither VOC, microplastic or the preservatives MIT or BIT

Pretreatment

The wood must stand raw and be cleaned of dirt, grease, algae and other possible dirt, so that the wood can absorb the oil. Basic cleaning is done with either wood cleaner or ammonia water and sanded if necessary. After cleaning, the wood must dry approx. 1 day before further treatment. If you want to lye the wood before applying the oil to avoid yellowing, the wood must dry for 1 day before oiling.

Application

The transparent oil is best applied with a wide brush with natural hair. The oil is worked well into the wood in a slightly fuller layer, preferably at both crosses & across the years and then along the years. The oil is left to stand for half an hour to allow the wood to absorb the oil, after which excess oil is wiped off with a lint-free cloth in the longitudinal direction of the wood. At the end of the work, the oil must have been worked completely into the wood and simply have a silky-thin oil film.

Be very careful with the cloths, which can ignite on their own !!! The cloths are drowned in water or packed in an airtight container.

Be aware that the type of wood, sanding and pore opening have an influence on the final expression of the treatment. For example, oily woods, or very finely sanded wood, will absorb less of the colored oil than very dry or coarsely sanded wood, whereby the intensity of the color may vary. If you want the color a little stronger, you can repeat the treatment as long as the wood still has absorbency.

Maintenance

Regular cleaning of the oil-treated surface is done in good soap shavings with a high fat content. If the treated surface needs nourishment, apply a thin layer of linseed oil with added desiccant to the cleaned surface. Wash the wood in the wood cleaner and let it dry approx. 1 day before oiling.

Coverage

Approx. 15 m2 pr. liters depending on the absorbency and nature of the wood.

Drying time

Approx. 24 hours. Curing 2-3 weeks.

Cleaning

Brushes are cleaned in concentrated liquid soap and rinsed in lukewarm water.

MAL code

00-1.

Safety

Cloths used during work can be self-igniting !!! They must therefore either be drowned, spread out so that the heat can escape during drying or be destroyed. Linseed oil dries by oxygen uptake. In that process, heat is developed. If the heat cannot escape, such as from a crumpled cloth, it can ignite spontaneously.

Specific References

Download

Pigmented oil for surface treatment of untreated wood.